Remote Monitoring and Analysis of plant machinery is a proven technology that can be used to compliment a conventional condition based monitoring program in order to improve reliability, equipment life, and worker safety.

Vibration analysis in particular is a key measure for any condition based monitoring program and provides an excellent indication of machine health.

Choose IVC for Remote Machine Monitoring

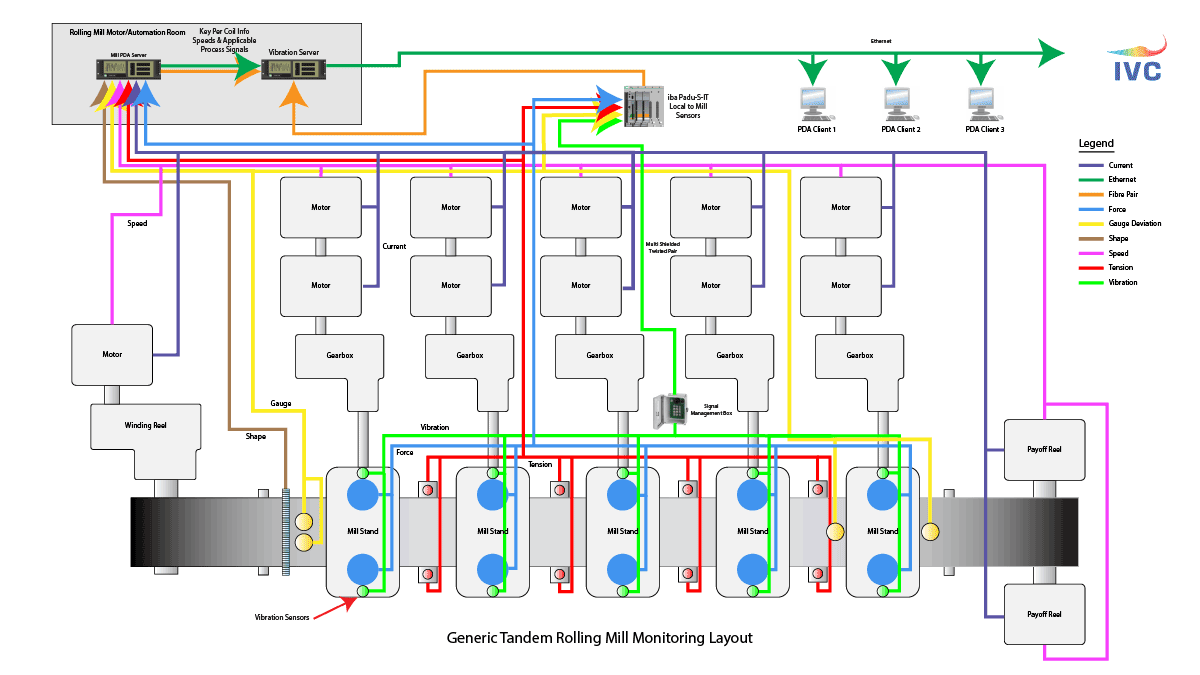

IVC can monitor multiple machines simultaneously and remotely provide diagnostic services. We have successfully implemented Remote Monitoring and PMP programs for the Steel, Paper, Petro-Chemical, and Power industries to identify and resolve a variety of machine issues, including:

- Imbalance

- Misalignment

- Looseness

- Resonance

- Bearing Faults

- Gear Defects

- Process related problems

Proactive Monitoring Can Help Improve Operations

Whether monitored locally or using remote monitoring, keeping track of your control systems and equipment operations can enable plant managers to make informed and strategic production decisions. IVC Technologies uses Accelerometers, Proximity Probes, Tachometers, and Process Control sensors to monitor and assess machine conditions. Our monitoring solutions efficiently qualify:

-

- Machine Transients, Startups, Shutdowns, and Process Change Events.

- Machine Commissioning and Overhauls.

- Plant Process Conditions.

If you are looking for remote monitoring based on wireless technology please visit our wireless solutions page.