Wireless CM is an evolving technology that needs to be properly deployed, continuously optimized, and closely supported, in order to maximize performance and account for some of the inherent limitations.

As a service-centric provider, we are committed to helping customers meet their reliability goals through custom solutions which maximize asset coverage and generate high-quality insights at a reasonable price point. We are not here to oversell and underdeliver.

Most systems on the market are very expensive (3-5X vs traditional alternatives) yet fail to meet customer expectations. Many plants complain of over-alarming, incorrect diagnostics, low sensor availability, etc.

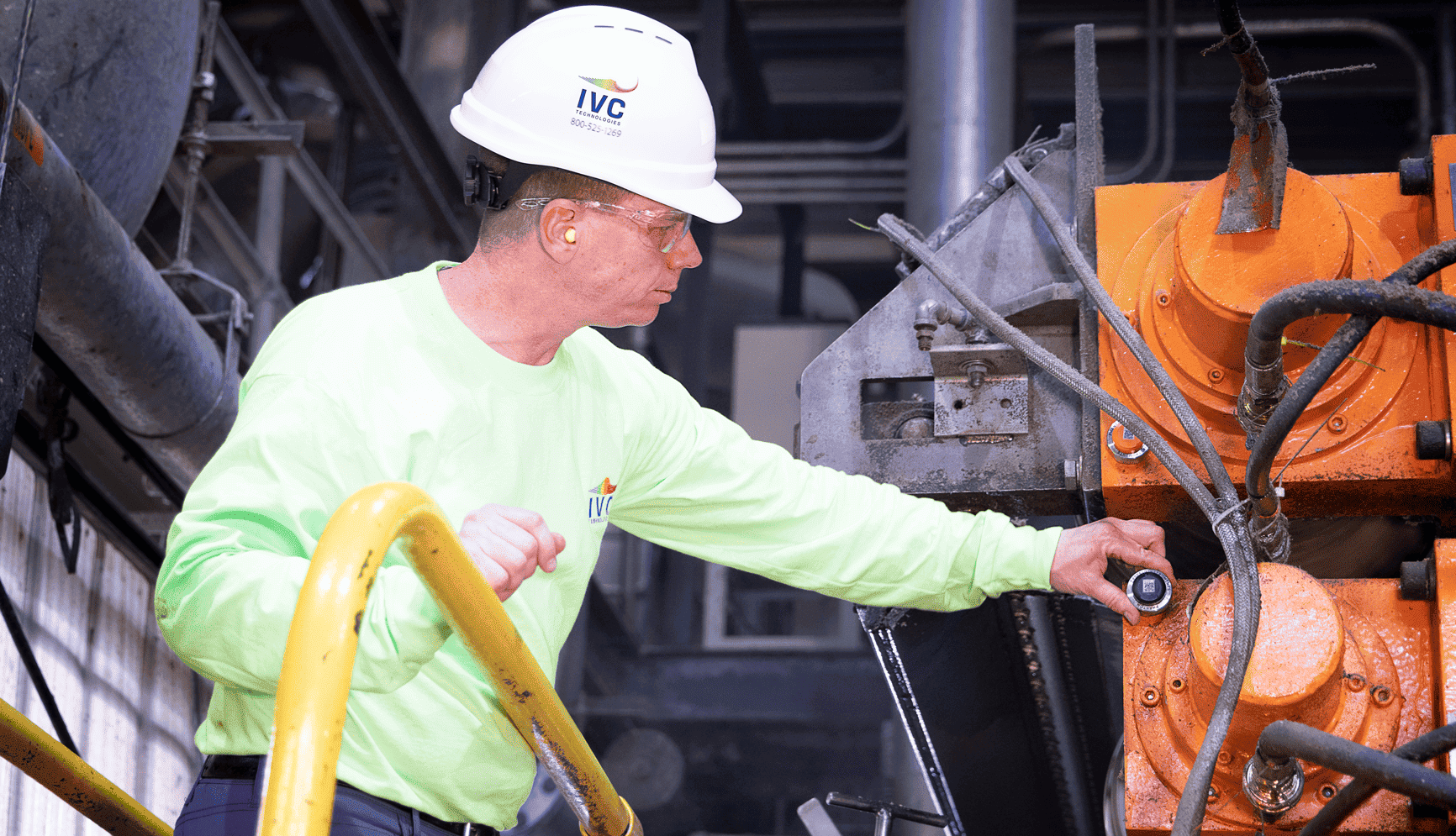

Our unique model is designed to eliminate those issues. IVC is the only provider that includes on-site system maintenance and continuous program optimization by leading CAT3+ experts in every package we offer, resulting in superior performance and excellent value.

What if one of our 50+ expert analysts is needed on-site? Most of our contracts include that as well! We are the only provider that offers integrated Hybrid programs where both remote analysis and on-site support are done by the same analysts (who knows your facility), and for a very competitive fixed monthly fee.

What if one of our 50+ expert analysts is needed on-site? Most of our contracts include that as well! We are the only provider that offers integrated Hybrid programs where both remote analysis and on-site support are done by the same analysts (who knows your facility), and for a very competitive fixed monthly fee.

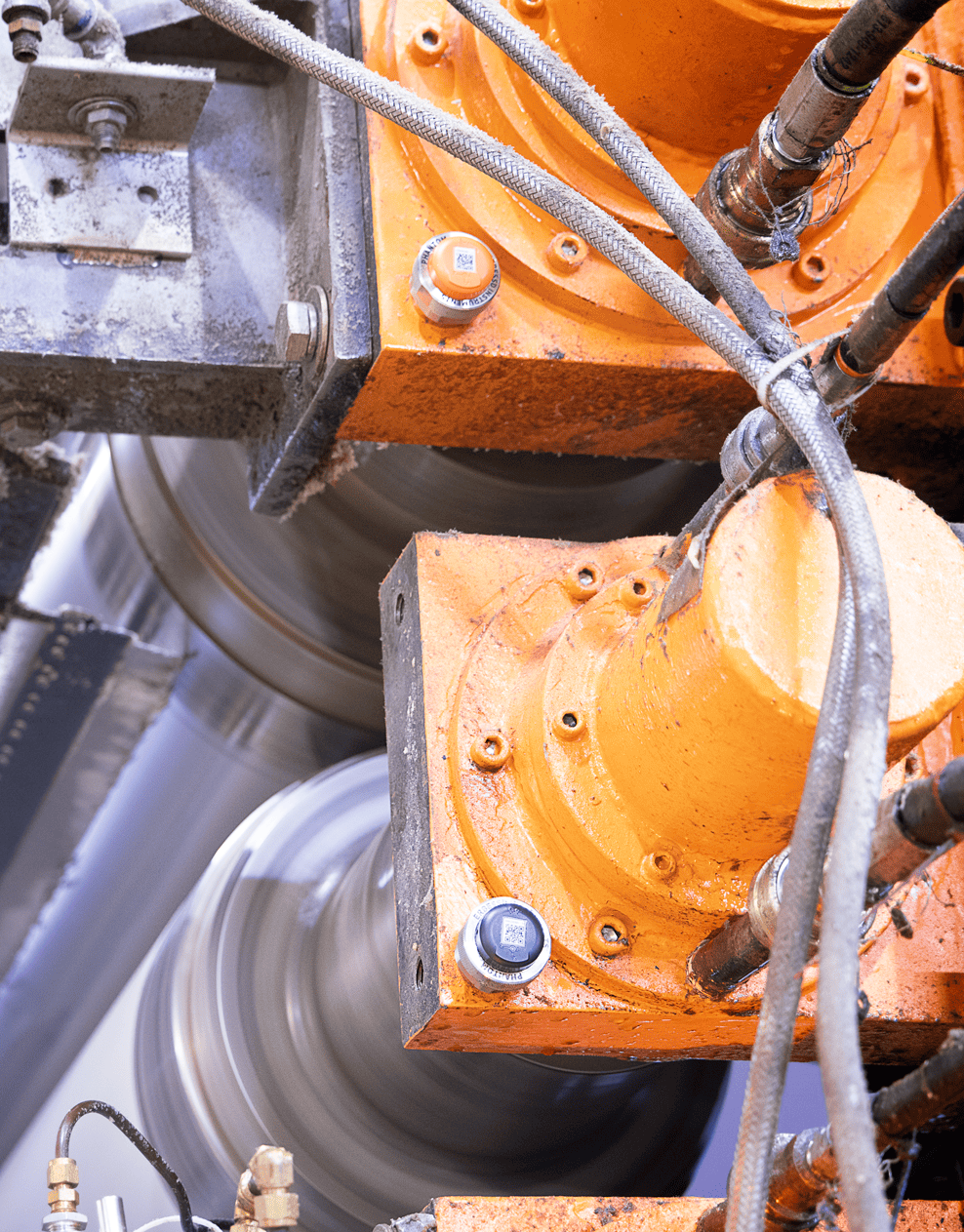

Wireless Vibration Sensors

- Erbessd Phantom Gen3 Triaxial sensor, 10kHZ Fmax in X&Y, 5.1kHZ in Z, with selectable resolution: 6400, 12800

- Smallest form factor on the market

- Long-lasting, low-cost, easily replaceable batteries (CR2477)

- IP69 level protection against dust, high pressure, and temperature

- ATEX Class2 grade sensors available

- Universal sensors available (vibration, temp, current, speed, etc)

Communications

- EI Gateway, with Bluetooth 5.0 (2.4HGz) link to sensors

- Cellular (or wi-fi) link to the cloud

- Modbus TCP/IP, OPC, MQTT protocols

- Rugged, flexible, proven solution for heavy industrial environments

- Can store 100k measurements offline (no data loss if connection is lost)

Online Cloud-Based Platform

- EI Analytics package for a scalable, real-time access and data processing

- Powerful tools to quickly analyze data and identify machine issues

- Harmonics, Sidebands, Filters, Markers, Orbits, and more

- Dashboards designed to efficiently organize data and explore trends

- Trending, Bad Actor Lists, FFT Visualisations, Current Values,

Full Turn-Key Solution with Remote Monitoring, Analysis, and Reporting

- Equipment lease (full OPEX) or Upfront purchase (CAPEX)

- On-site install & commissioning by qualified staff with vibration knowledge

- Remote analysis by USA-based certified analyst, dedicated to your account (no overseas techs)

- Continuous monitoring of surveillance alarms in line with our service standard

- Rapid response (verbal and written) to high alarms, with a detailed report for each critical event.

- Monthly (written) summary report, featuring in-depth analysis and recommendations for the assets where anomalies have been found.

- Biweekly “check-in” (summary) meeting between lead analyst and your team

- On-site system maintenance, battery replacements, system fixes, replacement of sensors.

- Cloud-based EI-Analytics portal showing machine status and basic data.