Soft foot is one of the most prevalent issues we encounter with rotating equipment when in the field. Also known as machine frame distortion, soft foot is a complex condition that can result in a wide range of mechanical and quality problems including misalignment, high vibration levels, accelerated wear and tear, premature bearing and seals failure, metal fatigue and distortion, and increased power consumption.

While not considered a critical situation, the consequences of ignoring the symptoms of soft foot can be quite serious and costly.

Note – companies get a reduced power rate when they use high-efficiency motors. However, these same motors are more sensitive to distorted frames due to the close clearances between the rotor and stator (i.e. “air gap”). This means that the energy saving may not be realized because of soft foot conditions.

Soft foot explained

An easy way to think about it is to liken it to a table where one leg is shorter than the other three. When someone leans on the table, the unevenness and lack of uniform contact with the floor causes a wobbling or rocking motion.

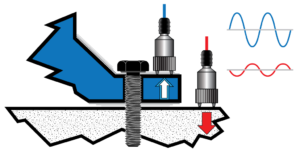

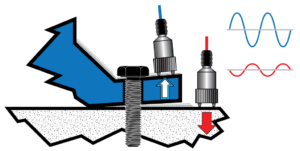

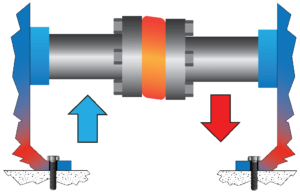

In rotating machinery, soft foot occurs when the machine is set into place on its frame and one or more of the machine’s “feet” are making little or no contact at the foot points of the frame. The result is a wobble or misalignment of machine parts.

While shoving a coaster or two under the short leg of a wobbly table works like magic to stabilize it, the process of mitigating soft foot in a machine is a bit more complex.

Common causes of soft foot

A combination of the following generally causes soft foot:

- Twisted, bent or warped frame or base plate

- Uneven or damaged foundation

- Twisted, bent, dented or damaged machine feet

- Too many shims under a foot

- Bent or deformed shim

- Dirt or debris under the feet

Common types of soft foot

There are several variations of soft foot commonly found in rotating equipment that includes:

Parallel

Parallel soft foot exists when a foot does not reach the base and creates a gap between the foot and the base. This condition is the easiest to detect.

Angular

Angular soft foot (aka “sprung foot”) occurs when a machine foot is touching the base on either the outside or inside portion of the foot, with the other side of the foot bent away creating an angle between the base and the bottom of the foot.

Squishy

Sometimes referred to as spring foot, squishy soft foot exists when the gap between the foot and base is filled with shims that have become worn out or contaminated by oil or dirt, impairing proper seating of the machine.

Stress-induced

Probably the most difficult soft foot condition to detect, stress-induced soft foot is caused by forces that are external to the machine. It can be the result of pipe strain, drastic misalignment or stresses induced by electrical connections. Eliminating this type of soft foot may require more than one check as stress-induced forces can be created at any stage of the alignment process.

Diagnosing soft foot

Once a soft foot condition is suspected, our analysts conduct a step-by-step diagnosis using a laser alignment system that includes a soft foot function.

The Soft Foot Wizard tool in the ROTALIGN Series by PRUFTECHNIK considers the differences in shaft deflection as each bolt is loosened or tightened. As our analysts tighten each bolt, the wizard reports the shaft alignment conditions in real time, revealing a soft foot problem that exists as well as the steps needed to correct it. Three-thousandths of an inch (0.003”) is considered excessive and needing correction. For comparison, the typical thickness of a sheet of 20-pound paper is about 0.004 inches.

Soft foot is a condition that can severely affect your machine’s operation. That’s why including a check for this condition as part of the pre-alignment process for your equipment is crucial.

If you suspect the existence of a soft foot condition in your machinery, further investigation is highly recommended. IVC Technologies’ analysts have over one hundred years of combined experience in a variety of industries. Using state-of-the-art laser alignment and vibration technology, we have helped our clients successfully address soft foot issues with their machinery. Contact us today to see how we can help to keep your assets running at optimum performance.