Stay Competitive and Profitable by Integrating Process and Condition Monitoring

Manufacturing companies wanting to remain competitive and profitable in today’s global economy are fast realizing the pivotal role that data and analytics play in improving operational efficiency and effectiveness. Integrating process and condition monitoring while harnessing the resulting data is a necessary first step in developing a strategic approach to decrease downtime and increase productivity.

Earlier this month, IVC had the opportunity to co-present a case study on this very topic at the International Machine Vibration Analysis and Condition Monitoring Conference (IMVAC) in Antwerp, Belgium.

Along with iba-AG Product Manager Christian Reinbrecht and Dr. Håvard Vold, we presented “Combining Process and Condition Monitoring – How to Bridge the Gap.” During our talk, we provided examples of the latest technologies that facilitate the merging of process monitoring and condition monitoring.

All data is not created equal

Data collection on rotating equipment is a key component to understanding the condition of your machines. However, not all data is created equal. If your data isn’t accurate, its subsequent analysis won’t be either. In addition, early warning signs indicating developing problems could be missed if data acquisition isn’t accomplished in a timely manner. These issues can result in costly downtime and lost productivity.

The tools and procedures used for integrating process condition monitoring deliver reliable and timely data in the measurement, evaluation, and qualification of influences in production machinery and the associated process control systems, as well as their effects on the produced product.

The three commonly used data collection methods include:

- Data Concentrators – A centralized PLC/Controller gathers messages from various underlying PLCs/Controllers and synchronizes them via timestamps from their respective sources into buffers that are passed to a data collection server.

- Asynchronous Re-Assembly – A centralized server gathers data buffers and/or data streams from various underlying PLCs/Controllers and synchronizes them via timestamps from their respective sources. Data buffers/streams are typically standardized for the server.

- Synchronous Multi-Stream – A centralized server gathers data streams from standardized interfaces and synchronizes them via the server’s internal timestamp.

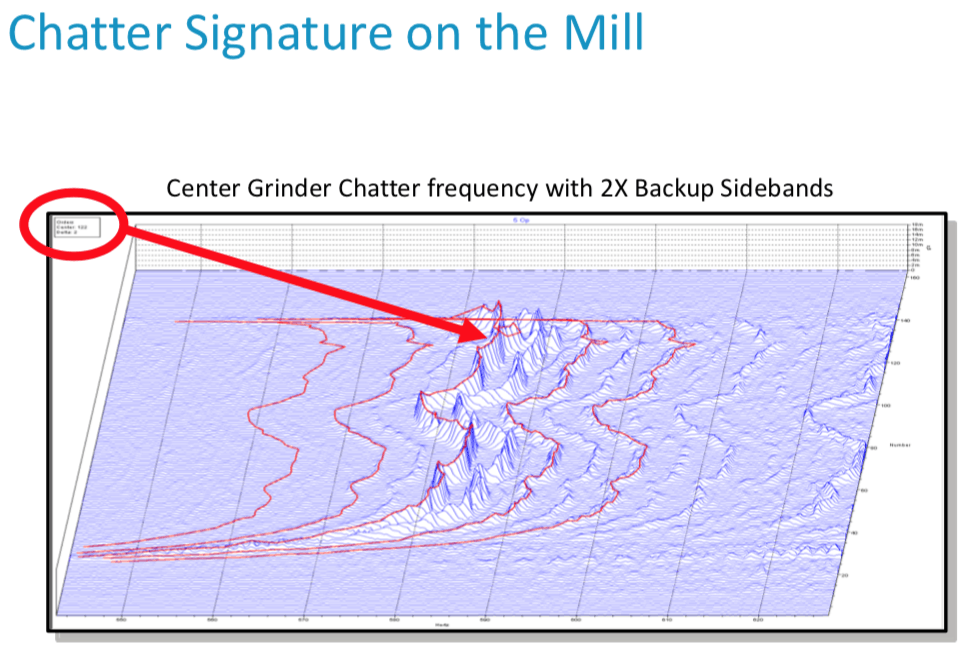

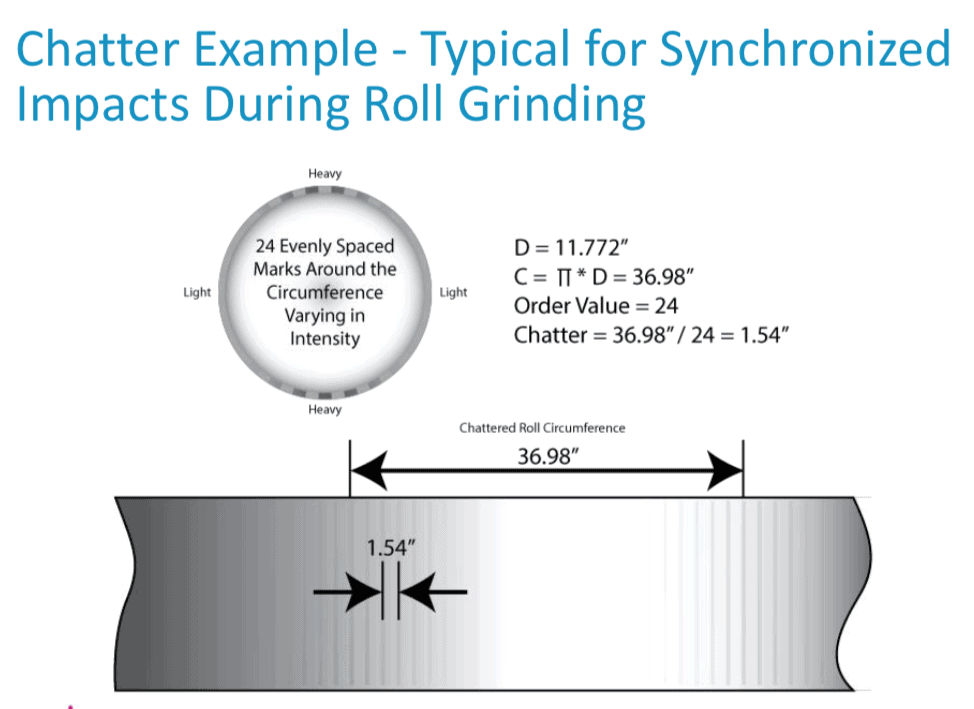

How integrated process condition monitoring helps solve Chatter

Both Rolling Mill and Roll Grinder chatter are quality issues that no manufacturer can afford. They result in lost production, increased conversion costs, and a loss of reputation and market share. Typical vibration analysis techniques fall short because they cannot characterize everything that occurs during the course of a coil or a grind with a single snapshot of data. Integrated process condition monitoring provides a decisive solution to a complicated situation.

Chatter Signature on the Mill – Integrating Process and Condition Monitoring

Chatter Example Integrating Process and Condition Monitoring – Typical for Synchronized Impacts During Roll Grinding

It’s not just about saving bearings

The IVC Technologies team focuses on analyzing and improving your process, production, and bottom line. We’re ready to help you tackle your toughest production and quality problems! Contact us to see how we can work together.