Whenever I overhear people state that ultrasonics captured a problem that vibration didn’t, it always makes me wonder if they know enough about vibration technology and vibration analysis or whether they are just repeating what they’ve heard from others over the years? Before accepting this statement as fact, you too may want to pause and ask several basic application questions.

Was the vibration capture point set up to capture that specific data?

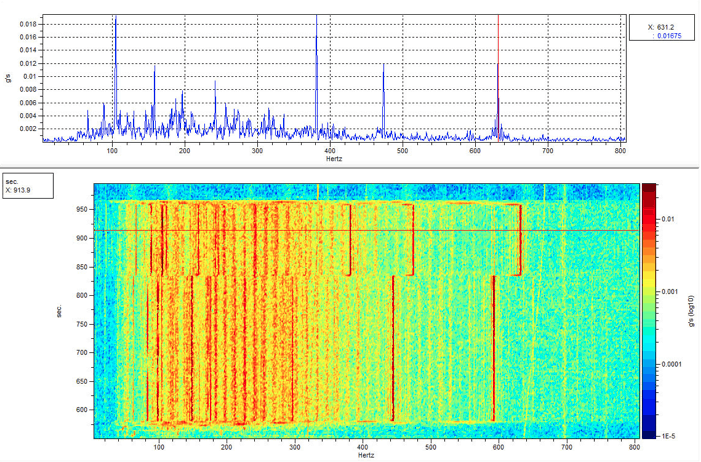

Vibration technology has a lot of adjustability from a frequency analysis perspective. You can adjust your frequency coverage, set up specific envelope frequencies, and even set up different lines of resolution to look for specific issues.

Having said that, if the vibration parameters are not set up to capture the data where the failure mode exists, you won’t see it. To arbitrarily say that vibration didn’t find a failure mode, means very little unless we know that the technology was used to its fullest possible capabilities.

Was the database set up correctly?

Many of the database reviews that IVC Technologies gets called in to assess aren’t set up correctly to capture the failure modes. The databases don’t go high enough in the frequency spectrum and don’t use resolution properly.

Many of the database reviews that IVC Technologies gets called in to assess aren’t set up correctly to capture the failure modes. The databases don’t go high enough in the frequency spectrum and don’t use resolution properly.

Were the failure modes for specific equipment types correctly set up and do you know which predictive technology can find them?

The first thing in any approach to predictive maintenance (PdM) or condition-based monitoring (CBM) services is to identify the possible failure modes and then decide what technology is applicable and how it should be applied. Maybe you will need to set up and view something in acceleration as opposed to looking at it in velocity. A solid understanding of the characteristics and nature of the failure mode will determine what will be required.

For instance, a pump has a different set of failure modes than a gearbox or rolling element bearing, so your vibration measurements have to be set up to apply to those specific applications.

Knowing how to set the proper parameters for the failure modes in any given equipment type is critical to using vibration technology and getting the most out of your investment.

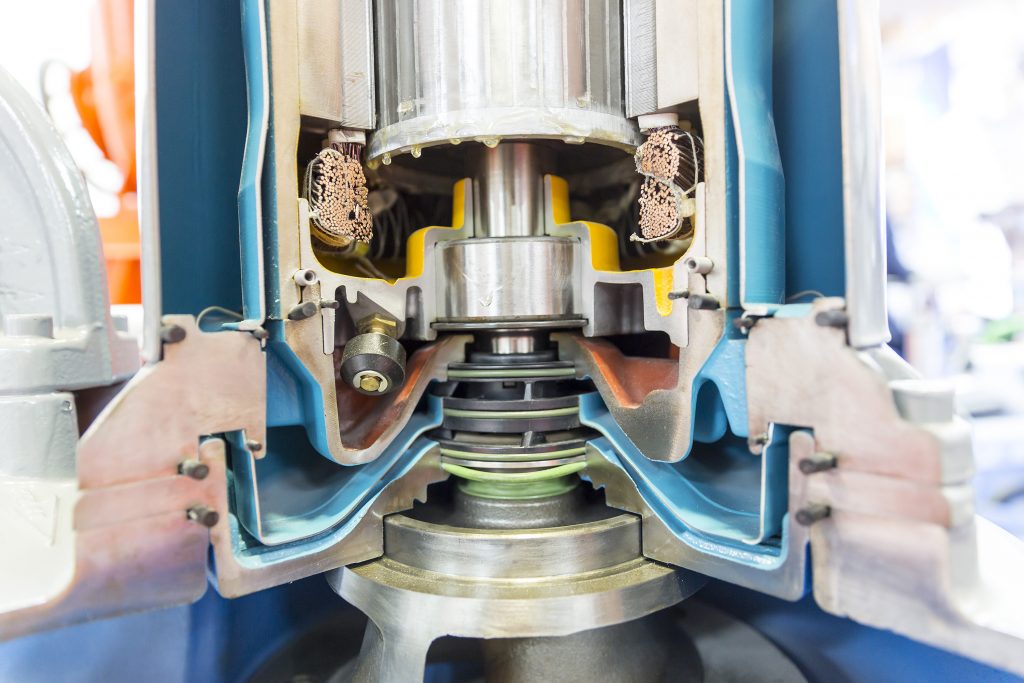

Do your people know what is inside the machines they’re measuring?

Most people don’t even know what is inside of a machine when they set up a vibration database. If you don’t know what is inside, what the internal configuration is, and what the machine is commissioned to do, then the database will have little chance of being set up correctly.

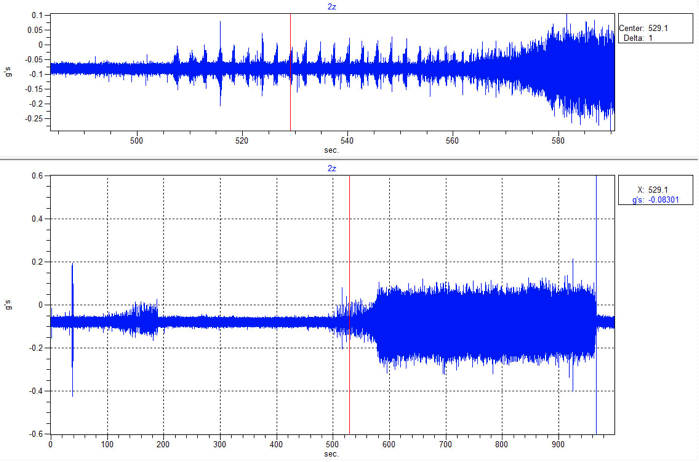

Are you relying on a limited understanding of the variability of vibration?

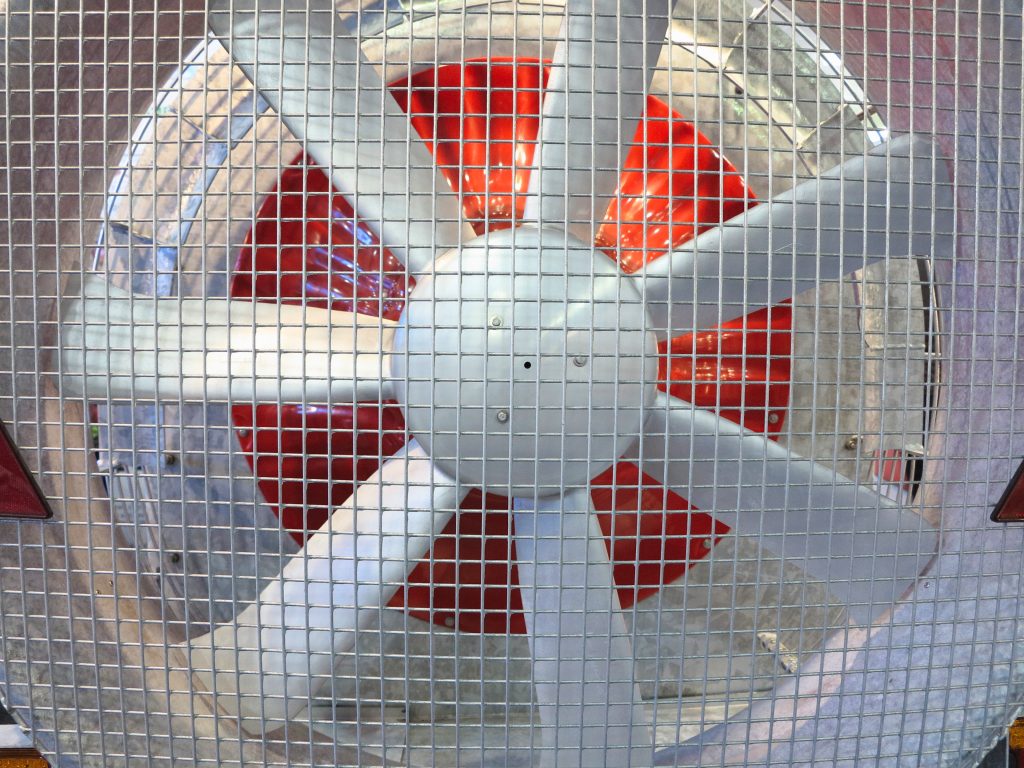

Case in point, we use the time waveform often to look at the waveform pattern to determine how much energy is being developed in a bearing. If for instance, you’ve got a fan that is moving material, then the waveform becomes pretty useless because it’s been impacted by the process of the fan.

In this instance, we have to rely more on the frequency content, and we have to disregard the time waveform. Not possessing a full understanding of the variabilities with vibration and how to set them up correctly in the database is most of the battle we find when we perform database assessments.

Using the right condition-monitoring technology for the equipment and possible failure modes will ensure you’re getting correct data to make decisions. This allows you to keep your facility’s critical production assets in optimal health and reliably provide the products and services your customers count on your company to provide.

IVC Technologies can help.

We offer training, vibration monitoring services, and database auditing and validation services. Our highly trained and certified professional vibration analysts review your database content, construction, analysis parameters, validating parameters for equipment types to enable identification of possible failure modes in the future.

IVC will prepare a comprehensive report and provide recommendations that are specific to your organization’s needs. You’ll have a roadmap and action plan for bringing your database up to standards. As your industry partners, we’re here to help at every step along the way to ensure your ongoing success.

Not sure you want to tackle that on your own? Contact IVC Technologies.