GO BEYOND OSHA ANNUAL INSPECTIONS FOR OVERHEAD CRANES WITH CBM

The goal of inspections and maintenance for overhead cranes according to OSHA should be focused on inspections for safety to avoid catastrophic failure. When the focus is on only meeting OSHA annual inspection requirements and not also upon improving the reliability of the equipment to perform its intended function, you are setting your operation up for unplanned downtime you can’t afford.

“Overhead cranes are a single-source cause of downtime in many industries.” Allen Bailey

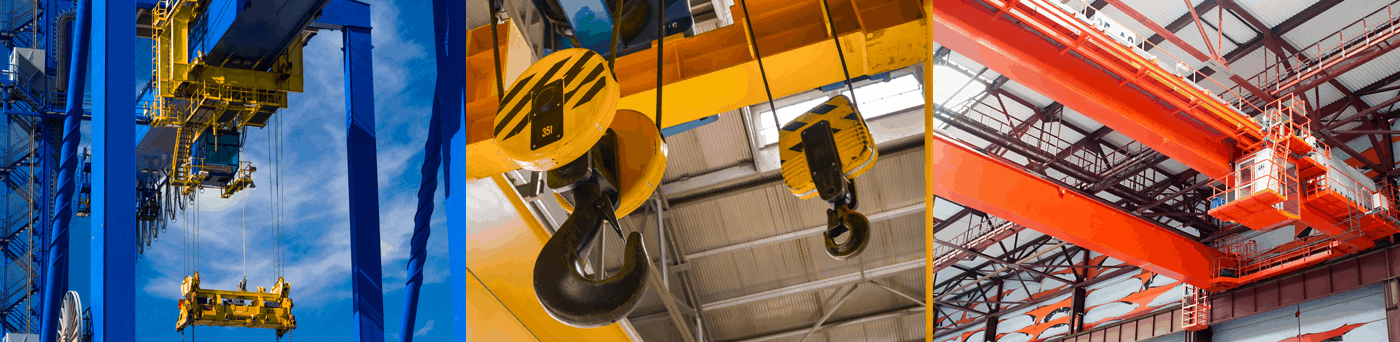

OSHA Regulation 1910 groups several equipment types together, primarily due to their similar travel characteristics. It addresses overhead and gantry cranes constructed and installed on or after August 31, 1971. This regulation is heavy on design, focuses on inspection for safety more than for the reliability of the cranes to operate optimally. To go beyond OSHA’s safety regulations and enable crane reliability requires new predictive technologies approaches.

Reliability: the probability that a component or system will perform its intended function for a specified period of time, under normal operating conditions.

Overhead cranes are some of the hardest assets in a facility to access for maintenance purposes; whether this is for routine Preventative Maintenance (PM) and Predictive Maintenance (PdM) inspections, troubleshooting, or for physical repairs. For this reason, your maintenance and reliability department may find overhead cranes some of the most challenging systems they oversee and maintain, and almost assures that the inspections and maintenance will be relegated to only scheduled outages or unplanned shutdowns. But it doesn’t have to be this way.

An Unfortunate Omission in OSHA Regulation 1910

There’s no mention of predictive maintenance (PdM) technology applications, specifically vibration analysis, which when applied, can provide insights for troubleshooting, inspection, trending, and analysis. Overall, the objective of applying vibration analysis would be to improve uptime and a crane’s ability to perform its intended function – Reliably.

We have additional resources that highlight new technologies available to end users and discusses their specific relevance when put into service for crane applications. These resources are linked below for your convenience.

Braden Bills says

It’s interesting that crane inspections are so important. It only makes sense that they would need to keep them safe! If they aren’t up to regulations, then the problems caused could be the source of a lot of damages.