Torsional issues are often the cause of mechanical failures in rotating equipment. However, if you are measuring motor current to provide a good analysis of torsional characteristics, you are likely missing critical data.

“How so?” you ask?

Motor current can provide a reasonable estimate of the torque at steady-state conditions, though not in complex drivetrains with multiple driven shafts. However, it cannot measure the actual driveshaft torque during transient or more significant torsional dynamic events.

Directly measuring the transmitted torque utilizing strain gage based torque telemetry is the most accurate method of measuring the actual torque on a shaft.

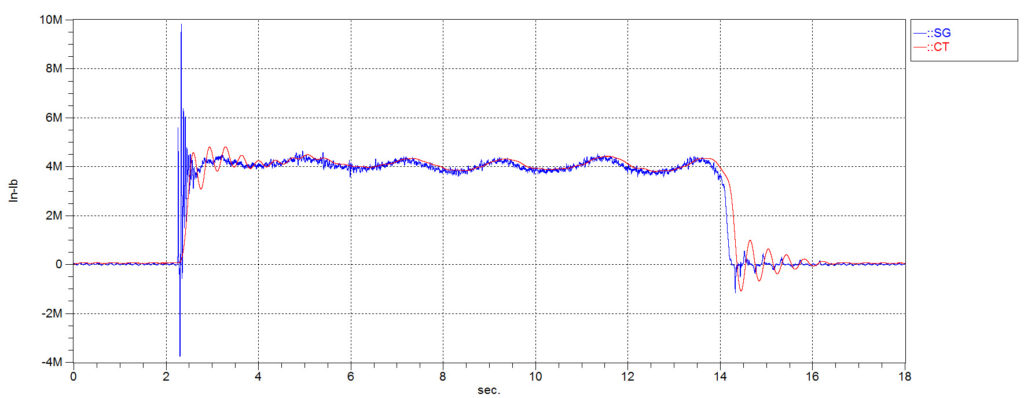

Case in point…Figure 1 illustrates the motor torque at a hot rolling mill during the rolling of a steel slab. The blue trace (SG) is the directly measured torque using strain gages. The red trace (CT) is the torque measurement based on the motor’s current transducer. Both traces have a similar amplitude during the middle of the slab at steady-state conditions. However, observing the slab entry, there is a significant difference between the strain gage measurement and the motor current measurement.

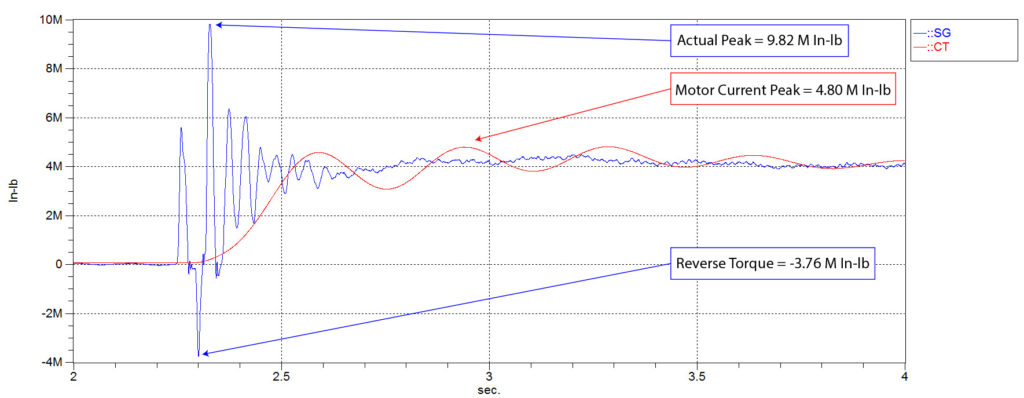

A closer examination of the slab entry (Figure 2) illustrates two potentially damaging conditions to which the motor current signal is blind. First, the actual peak torque is 9.82 Million Inch-pounds (M In-lb), whereas the motor current transducer only sees a peak torque of 4.80 M In-lb. In this case, the motor current signal only detects half of what the actual torque is. Second, there is a sizeable torsional reversal (negative torque) event that occurs at slab entry. The strain gage measurement recorded a reversing torque of -3.76 M In-lb. Reverse torque conditions can be extremely damaging to drive components, including shafts, keyways, and gearing. Again, the motor current transducer did not detect the reversing torque condition.

Relying on the motor current measurements for an indicator of actual torsional conditions can lead to incorrect assumptions of operating conditions – especially for machinery that may be experiencing repeated failures or undesirable performance.

Our Advanced Testing Group (ATG) has over 30 years of experience in addressing complex torsional issues. Contact us.