Misalignment is among the most common causes of excessive vibration in industrial equipment. If left unaddressed, it can lead to premature wear and tear on drive components that ultimately leads to premature failure.

Misalignment occurs when the motor and the driven component are not in correct alignment, or the component that couples the motor to the load is misaligned. Two common types of misalignment are angular and offset.

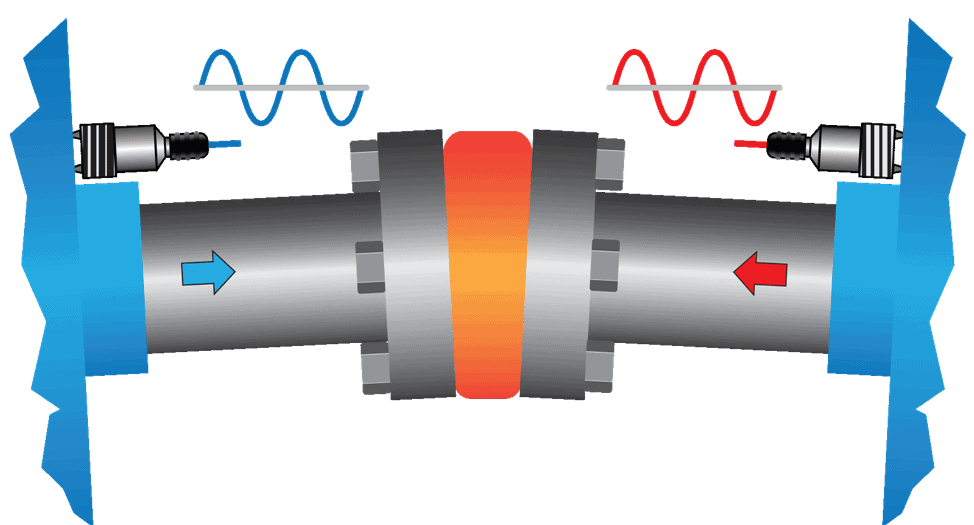

Angular misalignment (Figure 1) is when the shaft centerlines intersect but are not parallel.

Figure 1: Angular Misalignment

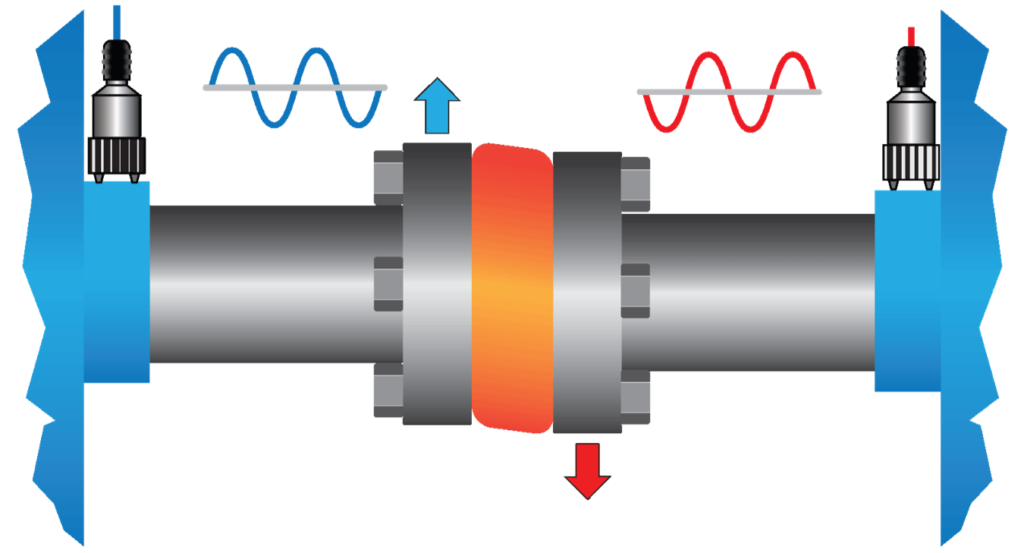

Offset misalignment (Figure 2) describes when shaft centerlines are parallel but not concentric.

Figure 2: Offset Misalignment

A common misconception is that installing a flexible coupling (versus a rigid one) will neutralize the negative effects of misalignment. Just because the couplings are designed to handle misalignment does not mean the bearings on either side are designed to do the same.

All Roads Lead to Regular Alignment

While flexible couplings are designed to withstand (without damage) some shaft misalignment, it doesn’t mean that machines can run efficiently under this condition without consequences. The reality is that even with a flexible coupling installed, a machine running with significant shaft misalignment will still transmit damaging cyclical forces along the shaft and into the motor, causing excess wear to the motor, an increase in mechanical load, and a decrease in the life of bearings and seals.

That’s why we always recommend that equipment be laser aligned to standard industry tolerances for shaft speeds as opposed to looser tolerances implied by flexible couplings. Contact us today.