Image courtesy of Electro Static Technology (AEGIS®)

Continual Bearing Failures on Your Drives? The Cause Might Surprise You

You’ve been diligent with the installation and maintenance of your industrial equipment. You’ve ensured that vibration levels are ISO compliant, balancing and alignment are within specification and bearings have proper fit, mounting, clearances, clean, and properly lubricated.

Yet despite all of this, the motor bearings continue to fail, sometimes shortly after replacing them and it’s getting expensive. What to do?

It’s time to take a step back and assess the bigger picture – are all the bearing failures related to motors controlled by variable frequency drives (VFDs)? If so, the bearing damage could be the result of Electrical Discharge Machining (EDM).

Variable frequency drives and EDM

The use of VFDs to control AC motors has increased dramatically in recent years due to their energy savings, low operating cost, and high performance. However, the challenge with VFDs lies in the potentially damaging electrical current (voltage) that is induced along the rotating motor shaft.

As the voltage accumulates on the shaft, the bearing lubrication acts as an insulator. When the voltage exceeds the dielectric strength of the lubrication, the voltage seeks the path of least resistance to the ground. That path is the metal component – typically the bearing or seal closest to the shaft. The electrical arcing to that component is called the electrostatic discharge.

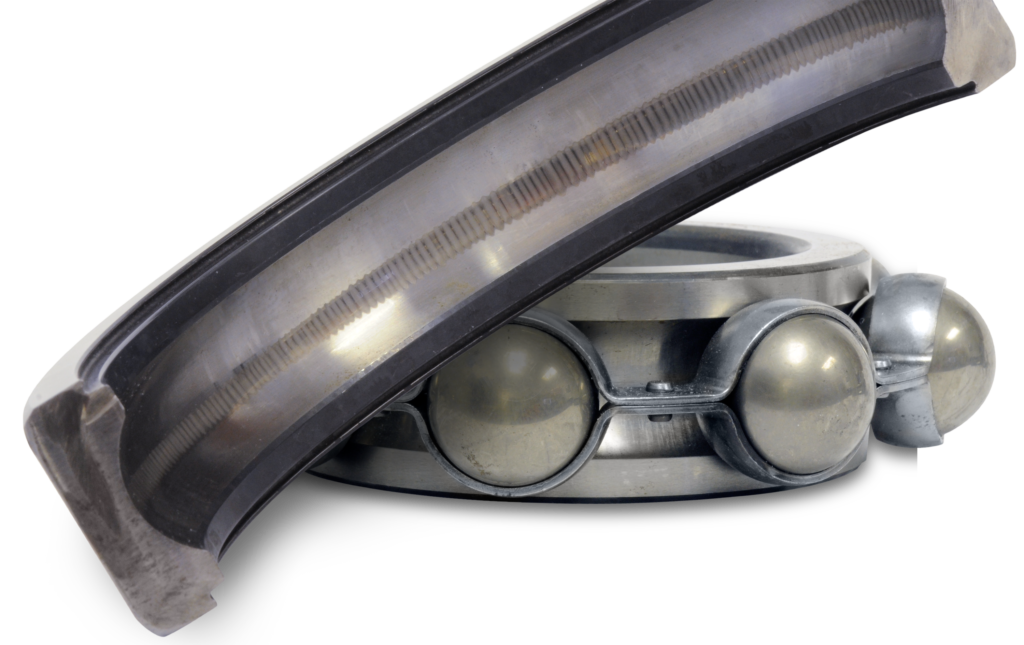

Frequent electrostatic discharging can cause EDM which creates three types of damage to the raceways and rollers:

- Pitting: Pits or fusion craters are caused when the electrical current passes from the shaft, through the inner race, through the rolling bearing elements, through the inner race, and then passing from the motor housing to the ground. These are generally not visible to the naked eye and require a microscope for identification. However, audible noises caused by the rolling elements riding over the pitting are often present. (See Figure 1 below)

Figure 1: Pitting Image courtesy of Electro Static Technology (AEGIS®)

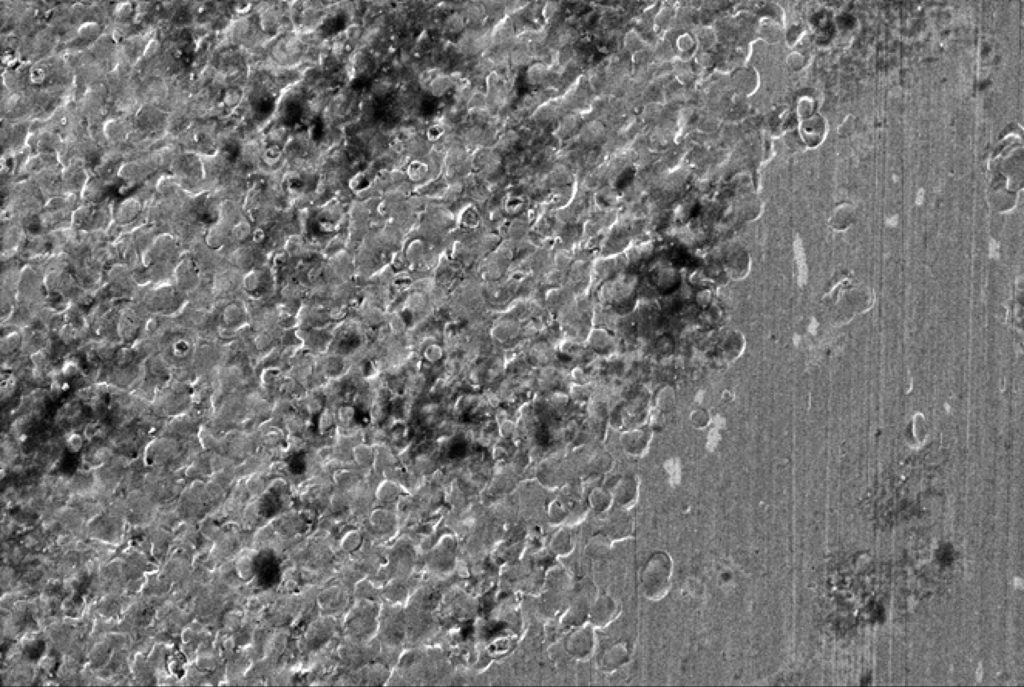

- Frosting: Frosting appears as a grayish discoloration, generated by either electrical or mechanical means and like pitting, often requires a microscope to identify. (See Figure 2 below)

Figure 2: Frosting Image courtesy of Electro Static Technology (AEGIS®)

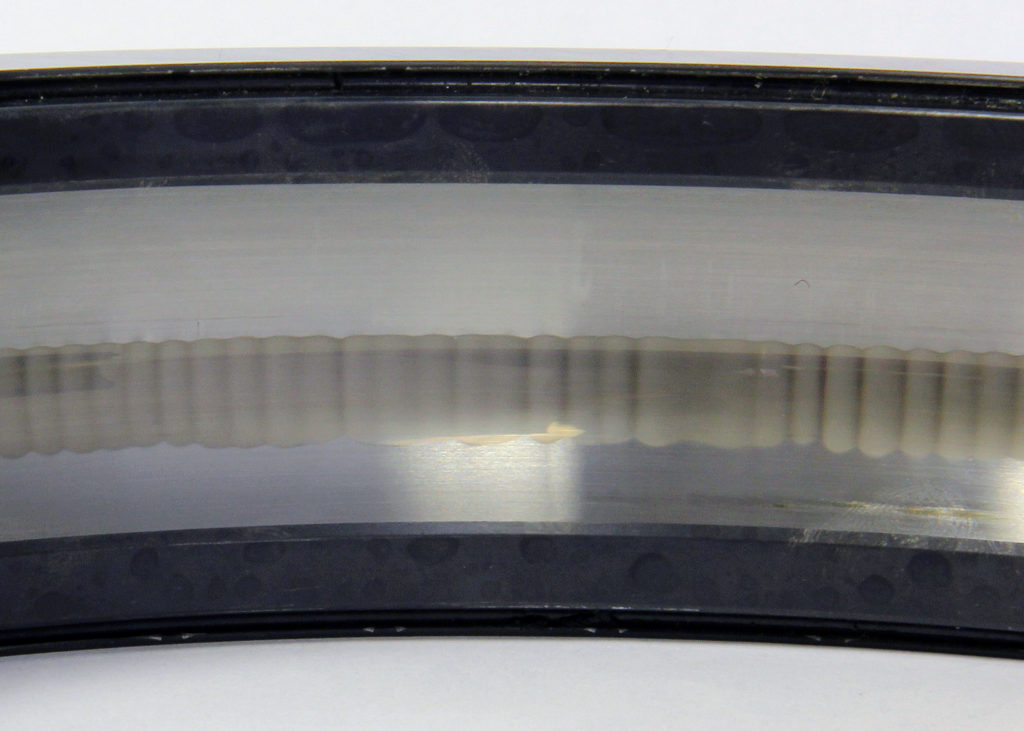

- Fluting: Fluting refers to concentrated pitting that occurs at regular intervals along the bearing raceway, creating a washboard-like pattern. It’s caused by the arcing of the current between the races and rolling elements, and unlike pitting and frosting, is visible to the naked eye. The presence of fluting is typically indicative of severe bearing damage, eventually leading to complete bearing failure. (See Figure 3 below)

Figure 3: Fluting Image courtesy of Electro Static Technology (AEGIS®)

Next Up: Identifying the Root Cause of EDM with vibration analysis and shaft-to-ground voltage/current analysis. Are you currently having issues with continual bearing failures on motors controlled by VFDs? We can help–contact us today.