The COVID-19 pandemic has created “new normals” for maintaining safety in manufacturing facilities.

While the COVID-19 pandemic certainly escalated the focus, maintaining employees’ health and safety in industrial environments has always been a top priority. But as vaccinations kick into high gear and “herd immunity” appears within reach, now is not the time to become complacent about safety. Safety awareness should always be at the forefront, and protocols to maintain it regularly assessed.

I sat down with Pete Roy, manager of Environmental Health and Safety for IVC, to discuss the pandemic’s impact on manufacturing safety protocols and regulations and how things are evolving for 2021.

Q: Well…2020 was fun (NOT!) What adjustments/additions to safety protocols did you make in response to the Covid-19 Pandemic?

A: Things unfolded pretty quickly in March and April of 2020 when the pandemic kicked into high gear. There was an avalanche of information to process and get up to speed on, not only on the virus itself but also the various regulations and restrictions that our customer base was rapidly implementing. Also, being a national company, we had to familiarize ourselves with each state’s protocols, which seemed to change fairly frequently.

We approached the pandemic from the viewpoint that communication was going to be the critical component to keeping both our employees and those of our customers safe. While our analysts work independently, their job requires them to visit multiple facilities, thereby significantly increasing their exposure risk. Everyone was understandably concerned for their safety as well as that of their family. We wanted to reassure our employees that they could feel confident that we kept them up-to-date on the latest information concerning general best practices and individual customer directives.

Q: OSHA recently released new guidelines for employers concerning safety and prevention. What are the most significant changes compared to the previous guidelines (if any), and how will this affect our field analysts, Full-Time Equivalents (FTEs), and customers during onsite visits?

A: The new OSHA guidelines for 2021 show two changes that will have no impact on IVC employees:

- The first one is not new to OSHA. It went into effect last year though it may be the first year they have documented it as a guideline. It primarily covers privacy changes in filling out injury reports where they no longer want to see the names of individuals.

- The second change also puts this topic into writing, covering COVID-19 information with 16 subsections regarding current best practices on the subject. We have implemented these items in our COVID-19 plan.

Q: What are the most significant safety hazards for IVC analysts when they are onsite?

A: Generally speaking, I think the various manufacturing processes each carry with them their own unique set of hazards. Thus, each company can have a completely different set of primary safety concerns and the issues commonly associated with typical industrial environments. So, generally speaking, in my opinion, the most significant safety hazards are:

- The first would be staying current/on top of changing conditions within our customer facilities from one moment to the next.

- The second would be the challenge of consciously maneuvering around potentially dangerous rotating equipment with an instrument in our hands that demands our attention to doing the best job possible acquiring data for later analysis.

Q: What safety training must our employees complete and how regularly?

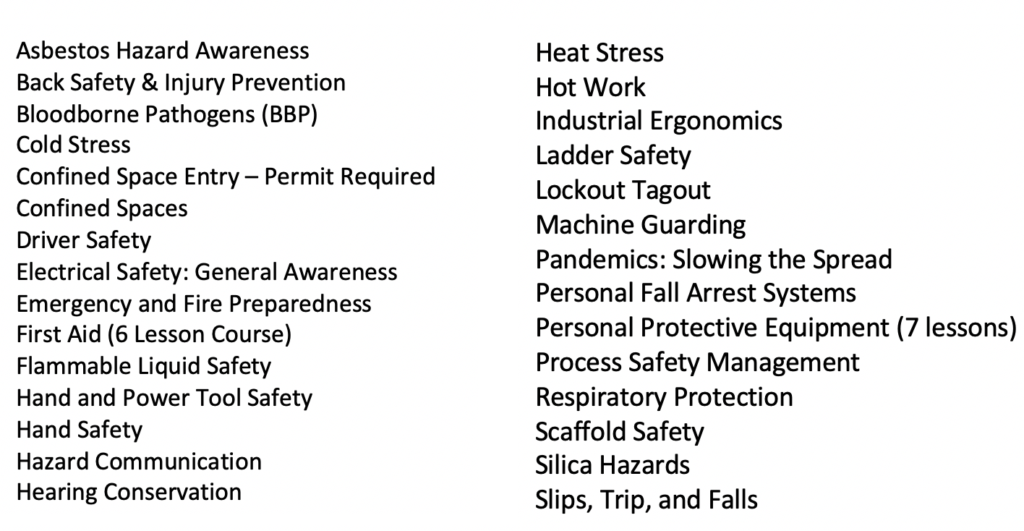

A: We have contracted with Vivid Learning for online training in 29 OSHA/MSHA standard compliance topics that are completed on a recurring monthly basis and include:

“Safety awareness is not a situational, circumstantial thing, and I think our approach has been successful so far, and I am looking to keep this trend going forward,” said Pete. “Keeping employees safe (our own and others) is and will always be a driving force in every aspect of how we conduct our daily business.”