It’s a scenario we see all too often…

Company “XYZ” wants to start the new year off on the right foot. So, they implement a condition based monitoring program (CBM) with all the latest IIOT bells and whistles…and then promptly ignore it for the rest of the year, except if an alarm goes off.

Fast forward to the end-of-the-year budget discussions. When cuts need to be made, all eyes turn to maintenance and the funds being spent on this CBM program that frankly, hardly seems worth all the hype with which it was installed.

That couldn’t be more wrong.

The reality is, Company “XYZ” is likely sitting on a gold mine of valuable data…it’s just that no one has been using it to its full potential.

This is when an audit (i.e. “assessment”) of the current CBM program can be a true game-changer for a company’s bottom line. (Don’t miss the 10% promo below)

Common issues uncovered with a CBM Program audit

The following are common issues that we see when called in to do an audit that are preventing companies from maximizing their CBM Program:

- Database setup incorrectly to capture failure modes

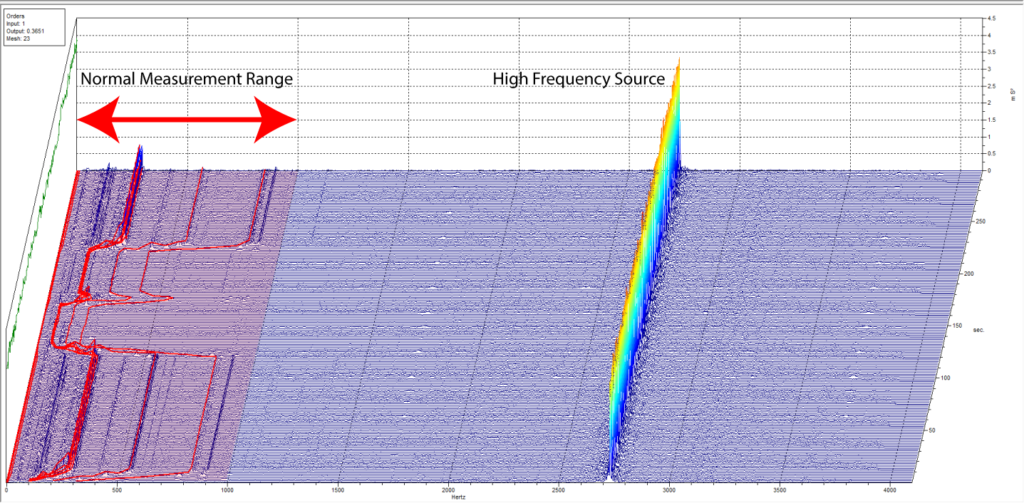

Vibration technology has a lot of adjustability from a frequency analysis perspective. You can adjust your frequency coverage, set up specific envelope frequencies, and even set up different lines of resolution to look for specific issues. If vibration parameters are not set up to capture the data where the failure mode exists, you won’t see it. Too often, the databases don’t go high enough in the frequency spectrum and don’t use resolution properly, so faults are missed.

- Wrong predictive technology applied to find failure modes

The first thing in any approach to predictive maintenance (PdM) or condition-based monitoring (CBM) services is to identify the possible failure modes and then decide what technology is applicable and how it should be applied. Maybe you will need to set up and view something in acceleration as opposed to looking at it in velocity or even changing to a different but complementary technology such as Infrared Thermography. A solid understanding of the characteristics and nature of the failure mode will determine what will be required. For example, a pump has a different set of failure modes than a gearbox or rolling element bearing, so your vibration measurements have to be set up to apply to those specific applications. Knowing how to set the proper parameters for the failure modes in any given equipment type is critical to getting the most out of your investment.

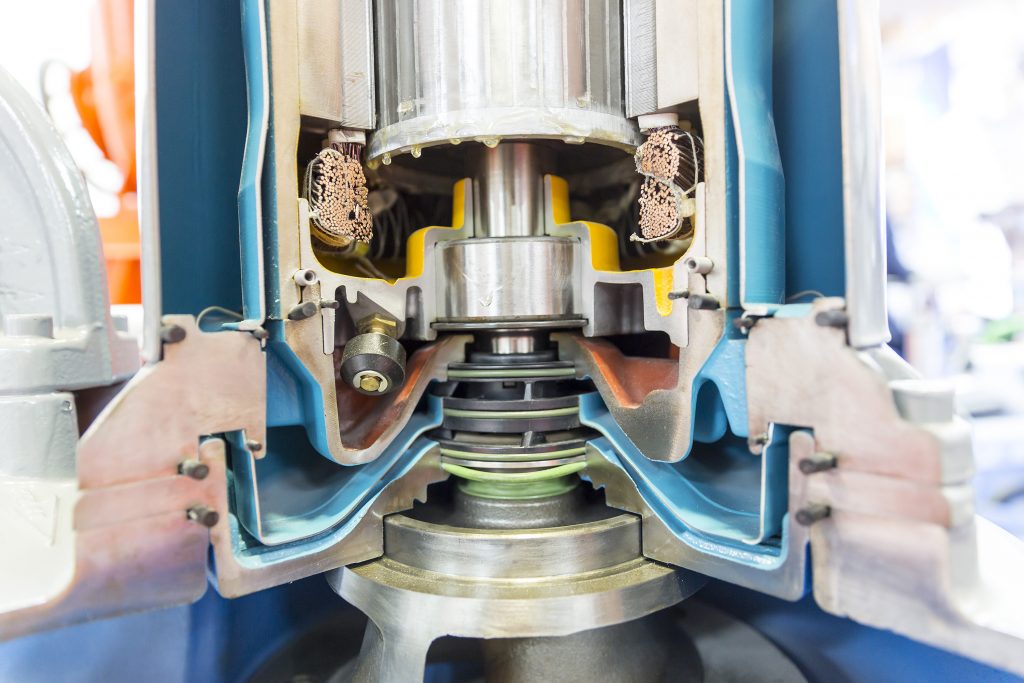

- A lack of understanding of what’s inside the machines being monitored

Most people don’t even know what is inside of a machine when they set up a CBM database. If you don’t know what is inside, what the internal configuration is, and what the machine is commissioned to do, then the database will have little chance of being set up correctly.

- Variability of vibration not considered

Not possessing a full understanding of the variabilities with vibration and how to set them up correctly in the database can lead to incorrect, essentially useless data.

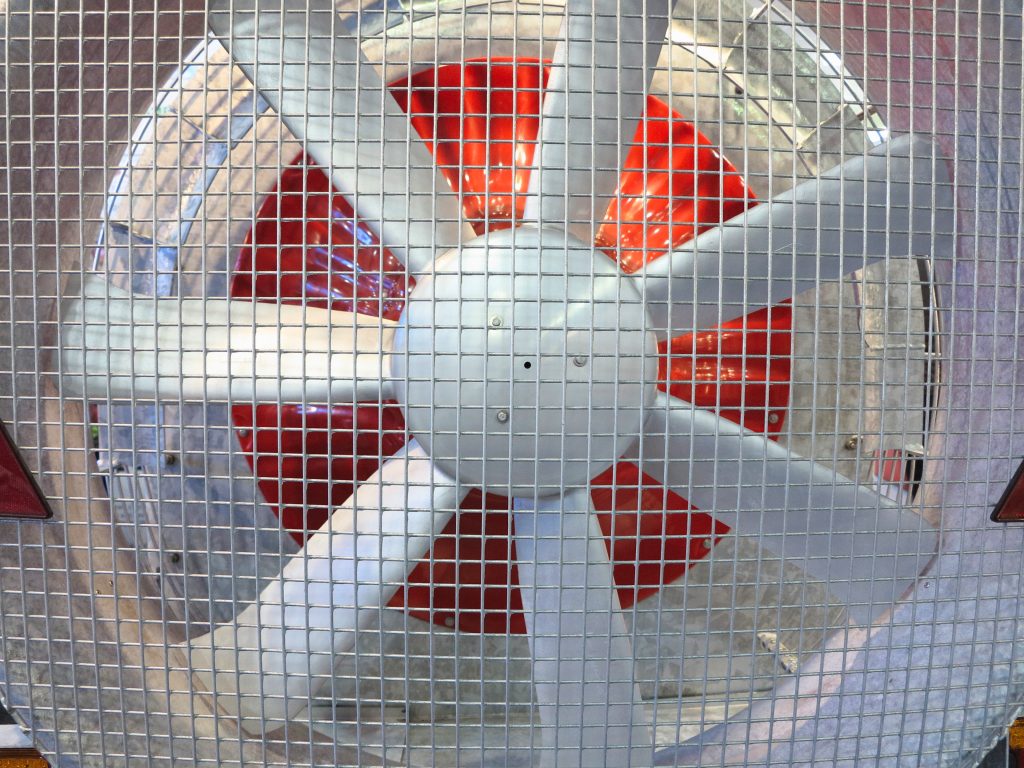

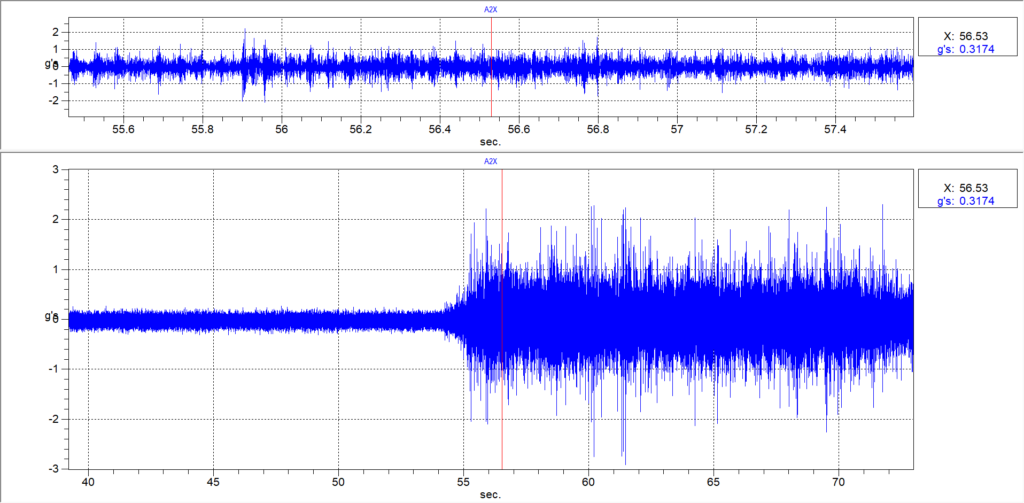

To determine how much energy is being developed in a bearing, we often use the time waveform to look at the waveform pattern. However, if you have a fan that is moving material, the waveform can become difficult to interpret due to impacting caused by the actual process as shown in the plot below. So, in this instance, a much more efficient analysis tool would be frequency analysis.

To determine how much energy is being developed in a bearing, we often use the time waveform to look at the waveform pattern. However, if you have a fan that is moving material, the waveform can become difficult to interpret due to impacting caused by the actual process as shown in the plot below. So, in this instance, a much more efficient analysis tool would be frequency analysis.

Don’t implement and ignore…tune in and tune-up your CBM program

Just like your car, your internal CBM Program needs regular tune-ups. IVC Technologies has over 30 years’ experience conducting multiple technology CBM programs in all types of industrial environments. We understand what it takes to make a program succeed and because we are always evaluating new technology, we can provide that insight to our clients.

To help you get a strong start in 2020, we’re offering 10% off for CBM Program audits scheduled before January 31st. Just click the “contact us” link below and in the “additional information” section of the form, type: PROMO2020.

IVC will prepare a comprehensive report and provide recommendations that are specific to your organization’s needs. You’ll have a roadmap and action plan for bringing your database up to standards. As your industry partners, we’re here to help at every step along the way to ensure your ongoing success.

Contact us to schedule.