Torsional issues can exist in a wide range of machinery with rotating components causing a variety of machine failures, operational instability, and product quality issues – all of which can have a huge negative effect on a company’s bottom line.

Torsional issues can exist in a wide range of machinery with rotating components causing a variety of machine failures, operational instability, and product quality issues – all of which can have a huge negative effect on a company’s bottom line.

An all too common mistake that many process engineers and other professionals make is in assuming that measuring motor current will provide an excellent analysis of torsional characteristics. However, relying on the motor current measurements for an indicator of actual torsional conditions can lead to incorrect assumptions of operating conditions – especially for machinery that may be experiencing repeated failures or unsatisfactory performance.

Why?

The current that flows through a motor is a function of the responses to the dynamic drivetrain conditions, drive control parameters and the physical properties of the motor. It is not necessarily a function of the actual torque on the motor shaft. While the motor current can provide a reasonable estimate of the torque at steady-state conditions, it cannot measure the actual driveshaft torque during transient or larger torsional dynamic events.

During these conditions, only direct measurement of the torque can provide a truly accurate assessment of the torsional characteristics. Additionally, even during steady-state conditions, the motor current cannot characterize the torsional conditions in complex drivetrains with multiple driven shafts.

Motor current “blind spot” when assessing torsional issues

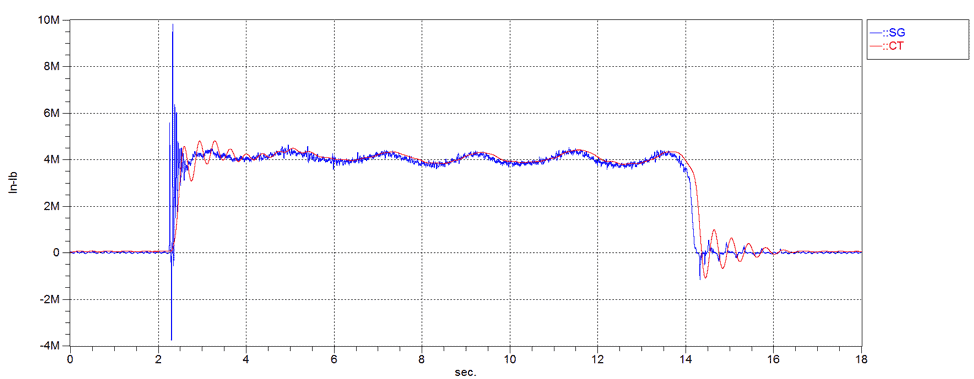

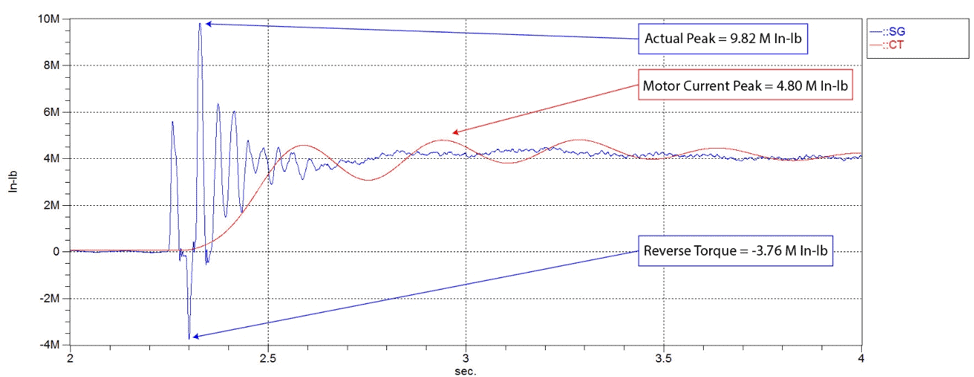

Figure 1 illustrates the motor torque at a hot rolling mill during the rolling of a steel slab. The blue trace (SG) is the directly measured torque using strain gages. The red trace (CT) is the torque measurement based on the motor’s current transducer. During the middle of the slab, both traces have a similar amplitude at steady-state conditions. Observing the slab entry, however, there is a significant difference between the strain gage measurement and the motor current measurement.

A closer examination of the slab entry (Figure 2) illustrates two potentially damaging conditions to which the motor current signal is “blind.” First, the actual peak torque is 9.82 Million Inch-pounds (M In-lb), whereas the motor current transducer only sees a peak torque of 4.80 M In-lb. In this case, the motor current signal is just detecting half of what the actual torque is. Second, there is a sizeable torsional reversal (negative torque) event that occurs at slab entry. A reversing torque of -3.76 M In-lb was recorded using the strain gage measurement. Reverse torque conditions can be extremely damaging to drive components, including shafts, keyways, and gearing. Again, the motor current transducer did not detect the reversing torque condition.

Strain Gage Based Torque Telemetry

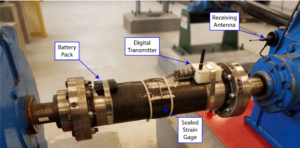

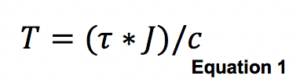

The most accurate method to measure actual torque is the use of strain gage based torque telemetry. The strain gage orientation and configuration can be designed to measure specific types of loading including axial, bending, or shear loading. Since torsional loading acts in the angular direction, it creates shear type loads at 45 degrees to the axis of the shaft. The general relationship between torque and shear stress is shown in Equation 1 where T is the torque, t is the shear stress, J is the Polar Moment of Inertia, and c is the distance from the center of the shaft:

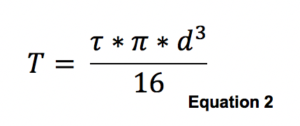

This equation can be rewritten to calculate the torque as a function of shear stress and reduced to be specific for solid circular shafts, which is shown in Equation 2 where d is the shaft diameter:

(A similar equation can also be derived for hollow shafts.)

A Secret Weapon in Asset Protection

Incorporating torque measurement with regular condition and process monitoring provides a unique advantage to keeping your machines running at optimal performance. At IVC, our world-class analysts utilize the industry’s most cutting-edge technology to acquire and analyze the torsional conditions of your equipment. In doing so, we are able to directly assess the operational requirements of a machine, detecting any inconsistencies and even design flaws.

Contact us for a comprehensive condition, process and torque monitoring plan tailored specifically for your company’s needs.

Want to dive a little deeper into torsional issues? Click here to download our white paper: “Torsional Issues: Stop Guessing and Measure the Problems Directly”