What is Infrared Thermography?

Infrared Thermography (IR) is a non-intrusive method used to monitor the condition of in-use equipment, based on temperature values. Infrared is a natural enhancement to the performance of visual inspections.

Thermographer using an infrared imager

As a condition-based monitoring (CBM) technology for manufacturing, infrared thermography is one of the most adaptable technologies with applications for mechanical, electrical, and stationary equipment uses. Once you know how to use a thermal imaging system properly, you will be able to see what you previously could not, and use the thermal information to help solve them.

Beware! IR Camera Experts warn that you will quickly see infrared thermal imaging equipment is not difficult to use. Although easy to use, misinterpretation is common with this tool.

How Does Infrared Thermography Work?

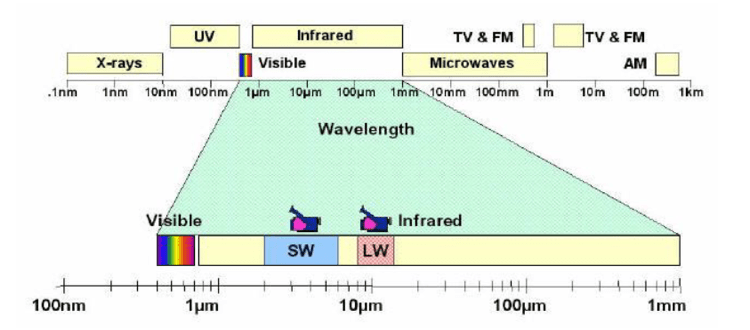

Wavelengths between 2 and 100 micrometers (µm) or microns in length are designated infrared radiation. The infrared detecting equipment commonly used are designed to detect radiation between 2-15µm.

With proper setup/use of your camera; and considering emissivity, relative humidity, wind speed, ambient temperature, background temperature, angle-of-view, spot size, focus, and range, you’ll get an apparent temperature of the surface being measured that is pretty close to precise. Exact temperature values can only be confirmed utilizing a contact probe, as conditions utilizing an Infrared Camera are rarely perfect.

Infrared Thermography of Mechanical Equipment Can Include, But Is Not Limited To:

Motors

Couplings

Bearings

Gearboxes

Belt Drives

Turbines

Boilers

Steam Traps

Welds

Conveyor Belts

Chillers

Centrifugal Pumps

Air Compressors

Tank Levels

Evaporators

Cautions When Using Infrared on Mechanical Equipment

- Buying an IR camera or infrared imager means you’ll need to know how to use your new tool and understand the theory of thermodynamics as well as limitations of infrared thermography as a predictive maintenance (PdM) technology; otherwise your readings will be unreliable.

- Your knowledge of the normal operating temperature measurements of the equipment you will be inspecting with infrared is important. Do you know the equipment well enough to compare similar equipment and know if it is running at optimal operating temperature?

- One way to understand your equipment better is to start trending your mechanical equipment infrared temperatures. Whenever a repair or remediation occurs, capture the baseline data in your CMMS system and note it as the normal operating temperature. This will help you catch the next fault sooner and possibly save other components that could be damaged. Documenting known faults can help you look for those efficiently in future scans.

Remember: Cost avoidance is important too!

- If you don’t know your plant processes, you may not understand when something is supposed to run ‘hot’ under certain parameters or operating conditions. Stay plugged in…know what’s going on with your equipment.

Strive to become the person in your plant or facility who knows the most about your critical equipment’s operating history and current condition.

- Understanding that atmospheric conditions like wind, humidity, rain, ice, sun, and reflectivity, for example, can greatly affect temperature measurements and data collection helps you gather better, more accurate data. Consider taking images during the same conditions each time, so you don’t get skewed data due to a difference of weather condition. You may want to postpone or reschedule your infrared inspection or scan if the situation permits or until a reasonable and similar operating condition presents itself.

- You may find that verification of a fault found with infrared can prove useful before deploying resources. In some instances, vibration analysis, oil analysis, and ultrasonic inspections can provide secondary measurements that clarify the exact nature of a fault. It’s helpful to know which technology will prove useful in different scenarios.

- Reliance upon Infrared Thermography and not observing with visual inspection for heat damaged components is a mistake made too often. Don’t be so reliant upon technology that you forget to use your eyes; you may see something that isn’t right. Infrared has its place, and so does visual inspection.

Never let your common sense go to waste.

If you don’t know or understand Infrared Thermography as well as you would like to, consider IVC Technologies’ Thermal/Infrared Testing training.